Whether you’re preparing your Tesla for a summer road trip or listing your classic Porsche for rent on Roadstr.fr, reliable filtration is essential for safeguarding your investment. In the world of automotive care, melt blown filter cartridges have become a go-to solution for oil, fuel, and fluid filtration. Before diving into vehicle-specific applications, understanding the broader role of melt blown filter cartridge manufacturing across industries provides important context for why these filters have become so trusted in automotive applications. Understanding how these filters work, where they fit into vehicle and maintenance cycles, and how to select and care for them can make a noticeable difference in performance, longevity, and rental profitability. This essential guide draws on the expertise of leading manufacturers, including Pullner Filter based in Songjiang District, Shanghai, with over 20 production lines and a 10,000 square meter cleanroom, to answer the practical questions car owners and renters have about melt blown filter cartridges.

Key Takeaways

- Melt blown filter cartridges use a multi-layered polypropylene structure for efficient filtration of oil, fuel, and automotive fluids.

- Selecting the right melt blown filter cartridge involves choosing an appropriate micron rating, size, and material compatibility for your vehicle.

- Premium manufacturers like Pullner Filter ensure quality and uniformity, making their melt blown cartridges reliable for both classic and modern cars.

- Regular maintenance and timely replacement of melt blown filter cartridges help prevent wear and ensure high vehicle performance.

- Fleet managers and rental operators benefit from standardized, certified melt blown filter cartridges for consistent protection across different vehicles.

What Is a Melt Blown Filter Cartridge?

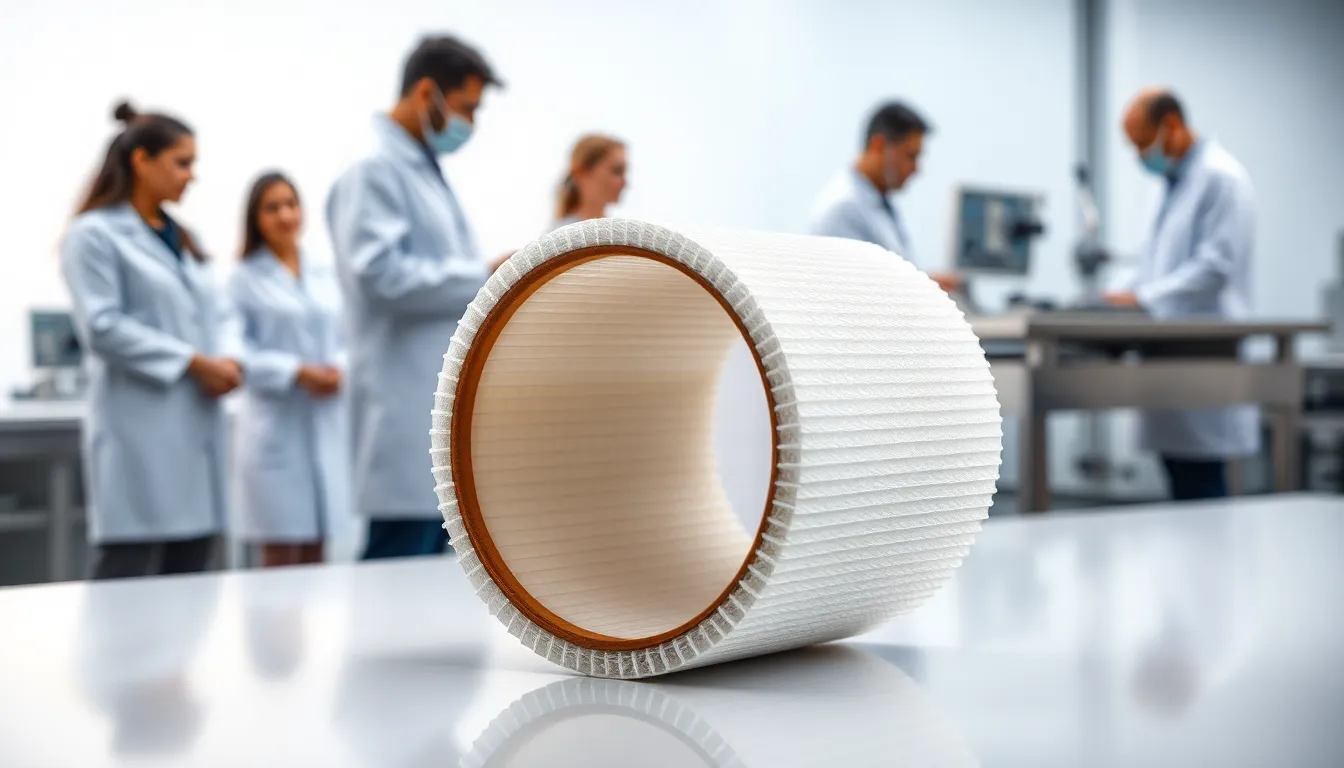

A melt blown filter cartridge is a cylindrical filter made from fine thermoplastic polymer fibers, most commonly polypropylene (PP). The manufacturing process involves melting the polymer, extruding it through tiny nozzles, and collecting the fibers on a rotating spindle. This process forms a multi-layered, gradient structure where the outer layers are coarser and the core is denser, allowing the cartridge to trap both large and fine particles as liquid passes through.

Pullner Filter, operating out of Songjiang District in Shanghai, produces melt blown filter cartridges in controlled environments, ensuring consistent pore size and fiber distribution. Their facilities offer strict quality control, enabling the production of filters with precise micron ratings, typically from 1 to 100 microns, making them suitable for a wide range of automotive and industrial applications.

How Melt Blown Filter Cartridges Work

In use, a melt blown filter cartridge allows liquid to enter from the outside and pass inward toward the center, often called depth filtration. As the liquid travels, particles are trapped at different levels within the increasingly dense fiber structure.

- Outside-in Flow: Liquid (such as engine oil or fuel) flows through the graduated filter media. The larger debris is stopped at the outermost layers while finer particles are retained deeper in the cartridge.

- Multi-stage Particle Capture: Multiple impingements mean high efficiency, with dirt and contaminants distributed throughout the filter medium, minimizing clogging and extending lifespan.

- Range of Micron Ratings: With available porosities typically from 1 to 50 microns (even up to 100µ), a suitable filter can be selected based on how fine the filtration needs to be.

Pullner‘s high uniformity, achieved with automated production lines, ensures that automotive systems, whether classic or high-performance sports models, get consistently reliable filtration.

Benefits of Melt Blown Filters for Vehicles

For vehicles, especially those intended for premium rental or frequent usage, melt blown filter cartridges offer several practical advantages:

- High Dirt-Holding Capacity: The depth structure captures a large amount of contaminants before flow becomes restricted, meaning longer service life and fewer replacements.

- Efficient Contaminant Removal: Filters can achieve high removal rates for particulates without affecting the taste or odor of any fluids, an important consideration in food-grade or sensitive systems.

- Thermal Stability & Durability: Most polypropylene melt blown filters remain stable at temperatures up to 80°C (176°F), making them suitable for hot climates or strenuous engine conditions.

- Corrosion Resistance: Polypropylene does not rust or degrade in the presence of oils, fuels, or mild chemicals used in automotive maintenance.

- Low Pressure Drop: Optimized pore structure reduces the load on pumps, improving overall system efficiency and protecting sensitive components.

With these features, vehicles listed for rent, whether classic convertibles for weddings or electric SUVs for family trips, gain protection against premature wear caused by contaminants. Pullner Filter’s commitment to high-quality production ensures each filter meets the necessary standards for reliability across industries.

Applications of Melt Blown Filter Cartridges in Automotive Maintenance

Car owners and commercial rental operators benefit from melt blown filter cartridges in several common automotive systems:

Engine Oil Filtration

Trapping fine metallic and dust particles in engine oil, these filters prevent abrasive wear and clogging that can harm high-value vehicles, especially in older or high-mileage cars frequently rented out with platforms like Roadstr.fr.

Fuel Pre-filtration

A melt blown filter installed upstream from sensitive fuel injectors or pumps removes particulates that could compromise efficiency or cause performance issues, particularly important for premium and sports models.

Fluid Purification

Beyond oil and fuel, melt blown cartridges are used to filter transmission fluids, coolants, and even washer fluids, keeping every system running smoothly.

Protection in Rental Fleets

For those managing multiple vehicles for rental, standardizing on a trusted melt blown cartridge (with NSF or equivalent certification) helps ensure consistent protection across mixed car fleets. Pullner Filter’s large-scale, cleanroom manufacturing allows them to supply volume requirements with traceable quality controls.

How to Choose the Right Melt Blown Filter Cartridge for Your Car

Selecting an appropriate melt blown filter cartridge depends on several key factors:

- Micron Rating: Lower ratings (1–5µ) are ideal for fine particles: 10–25µ works well for general automotive fluids. For engine oil, aim for 10µ or finer, while 20–50µ is often suitable for pre-filtration.

- Filter Length and Size: Common cartridge lengths range from 5 to 70 inches. Consult your vehicle documentation or a filtration specialist to confirm what fits your housing.

- Material Compatibility: Polypropylene is standard for automotive uses due to its chemical inertness and temperature stability, but durability and certifications matter. Pullner Filter’s products are manufactured to international standards, offering dependable options for both modern and classic vehicles.

- Flow Rate: A standard 10″ filter supports up to 1m³/hour: check the flow requirements of your system to avoid restricting performance.

- Certification and Approval: For health and safety, filters rated by agencies like NSF are preferred, especially in sensitive uses (for example, in vehicles crossing food or pharma zones).

Professional suppliers such as Pullner Filter can advise on correct cartridge selection for both individual vehicles and rental fleets.

Installation and Maintenance Tips

Proper installation and routine maintenance ensure full benefit from melt blown filter cartridges:

- Installation: Confirm compatibility with the filter housing and check all O-ring seals. Align the cartridge for a straight fluid path: leaks or poor fit can compromise filtration.

- Monitoring and Replacement: Replace cartridges when a pressure increase signals that dirt-holding capacity is reached, or at mileage/intervals suggested by the filter manufacturer. High-capacity filters extend the interval between changes, ideal for fleets or busy owners.

- Temperature Considerations: Polypropylene melt blown filters are rated for continuous service up to 80°C (176°F), with a maximum of 95°C (203°F) for short periods. Avoid use in higher temperature or aggressive chemical applications.

- Cleaning: Disposable by design, these filters should be replaced rather than cleaned: reuse can risk partial filtration or bypass.

Pullner Filter’s technical team supports customers with installation advice and recommended replacement cycles, helping rental operators and private owners maximize equipment uptime and minimize unexpected maintenance issues.

About Pullner

Business: Pullner

Spokesperson: Lucy

Position: Sales Manager

Phone: 0086-21-57718597

Email: [email protected]

Location: LB19-Office No.1207, Jebel Ali Free Zone, Dubai, United Arab Emirates

Website: https://www.pullnerfilter.com/

Google Maps Link: https://maps.app.goo.gl/XgLZWHjGFcmdWddt6

Frequently Asked Questions about Melt Blown Filter Cartridges

What is a melt blown filter cartridge and how does it work?

A melt blown filter cartridge is a cylindrical filter made from fine polypropylene fibers. It works by using a gradient structure: larger particles are trapped on the outside layers, while finer contaminants are filtered out deeper within. This depth filtration method ensures effective removal of impurities from automotive fluids.

Why are melt blown filter cartridges important for vehicles?

Melt blown filter cartridges are essential for vehicles because they offer high dirt-holding capacity, efficient contaminant removal, thermal stability, and chemical resistance. These features help protect engine and fluid systems from abrasive wear and prolong the lifespan of automotive components, especially in rental or high-use vehicles.

How do I choose the right melt blown filter cartridge for my car?

To select the correct melt blown filter cartridge, consider the micron rating (finer for engine oil, coarser for pre-filtration), cartridge size and length, material compatibility (polypropylene is standard), flow rate, and certifications such as NSF. Consulting your vehicle manual or a filtration specialist ensures an optimal match.

What maintenance do melt blown filter cartridges require?

Melt blown filter cartridges should be installed with proper fitting and O-ring seals, monitored for pressure increases indicating replacement time, and replaced rather than cleaned, as they are disposable. Adhering to routine maintenance helps maintain system efficiency and prevents inadequate filtration.

Can melt blown filter cartridges be used for all types of automotive fluids?

Yes, melt blown filter cartridges are versatile and can be used for engine oil, fuel pre-filtration, transmission fluids, coolants, and washer fluids. Their broad chemical compatibility and customizable micron ratings make them suitable for various automotive maintenance applications.

What are the differences between melt blown filter cartridges and pleated filter cartridges?

Melt blown filters use a depth filtration structure to trap contaminants throughout their thickness, offering high dirt-holding capacity. Pleated filters, by comparison, have more surface area for fine particle capture but may clog faster. The choice depends on the fluid type and required service interval.